WATER SOLUBLE CUTTING OIL

NEW GENERATION

MULTI MACHINE MULTI APPLICATION

SUITABLE FOR ALL METAL and ALLOYS

BIOSTABLE BACTERICIDE FREE

The definitive solution for your problems

of managing soluble oil baths

DESCRIPTION

|

A cutting fluid is essentially used for four reasons

|

|

|

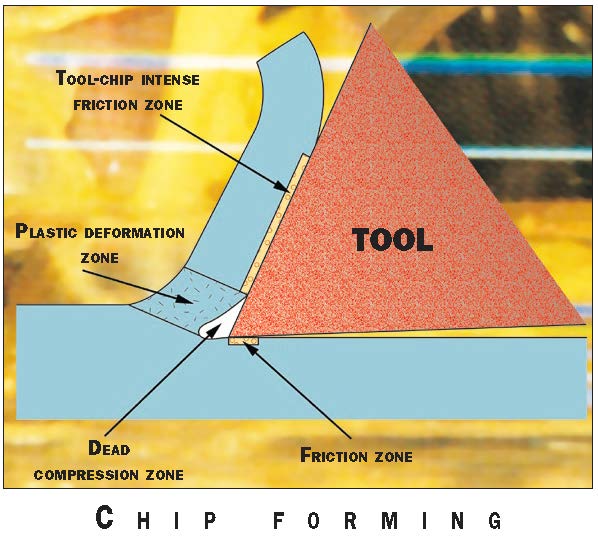

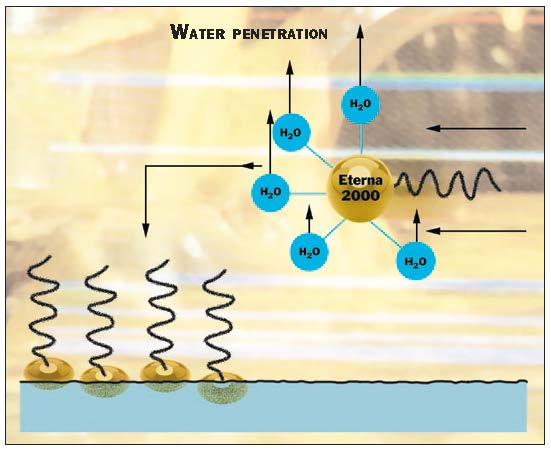

TO MAKE 1 AND 3 WORK EFFICIENTLY : THE LUBRICANT HAS TO PENETRATE BETWEEN THE CHIP AND THE TOOL.

The cutting fluid must have an exceptional wetting power to do this : penetration at the interface by capillary action.

|

||

|

Tool wear results from very severe mechanical loads,

|

||

|

|

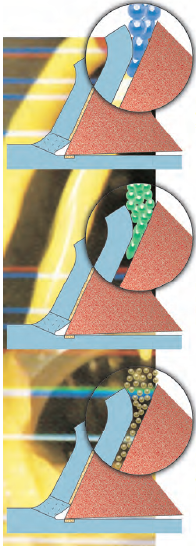

Congestion of emulsion molecules does not allow for sufficient penetration

Congest ion of micro-emulsion molecules is less, but penetration

The infinitely small molecular congestion with ETERNA® 3000 allows for complete penetration between the tool and the chip. This is the nanolubricating principle. |

|

|

ETERNA® 3000 PENETRATES THE TOOL INTERFACE

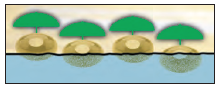

ETERNA® 3000 Reacts strongly with the machined surfaces

|

||

|

||

|

The ETERNA® 3000 active molecules convey water to the interface.

|

||

|

|

||

|

- Simultaneously, the ETERNA® 3000 molecules react and are vigorously adsorbed by the machined surfaces. In this manner, they considerably reduce the friction coefficient.

|

||

FIELDS OF USE

|

Production operations |

% recommended uses |

|

Turning, small parts turning |

from 5 to 8% in water |

|

Milling, face milling, slotting |

from 5 to 8% in water |

|

Drilling, boring, threading, tapping |

from 6 to 10% in water |

|

Sawing |

from 5 to 8% in water |

|

Trimming of soft metals |

from 8 to 12% in water |

|

Finishing operations |

% recommended uses |

|

Sharpening |

from 4 to 6% in water |

|

Boring |

from 4 to 6% in water |

|

Flat or cylindrical grinding |

from 1.5 to 2.5% in water |

|

Polishing |

from 1.5 to 2.5% in water |

Note: the refractometer correction factor of ETERNA 3000 is 1.5.

A 4% reading with a refractometer will establish a bath concentration of 6%.

Machinable metals:

Steels, stainless steel, Inconel, Monel, aluminium and its alloys (except aluminium with silicon), copper and its alloys, CFRP including sandwiches, GFRP.

PHYSICO-CHEMICAL PROPERTIES TYPICALS

|

PHYSICAL PROPERTIES OF THE LUBRICATING OIL |

|||

|

PROPERTIES |

STANDARD or METHOD |

VALUE |

UNITS |

|

Appearance |

visual |

Clear |

nm |

|

Colour |

Visual |

Yellow to brown |

nm |

|

Scent |

Olfactory |

Light, characteristic |

nm |

|

Density at 25°C |

NF EN ISO 12.185 |

1056 |

kg/m3 |

|

Freezing point |

ISO 3016 |

-4 |

°C |

|

Viscosity at 40°C |

ISO 3104 |

16.7 |

mm²/s-1 |

|

Refraction index |

|

1.4240 |

|

|

pH |

ISO 4925 |

8.6 at 5% |

|

|

HERBERT test |

IP 287 |

goes to 1 |

% |

|

Cast iron/stainless steel corrosion |

CNOMO |

goes to 1 |

% |

|

Foaming test: at 5% Th 35 at 5% Th 20 at 5% Th 0 |

NF T 60.188 |

300/40/0/0/250 300/40/0/0/250 300/100/0/0/250 |

|

|

Chlorine content |

argentometry |

<20 |

ppm |

|

Sulphur content |

gravimetric analysis |

<50 |

ppm |

|

Nitrite content |

redox |

0 |

|

|

Boron content |

potentiometry |

0 |

|

|

Phosphorus content |

calcination/colorimetry |

0 |

|

|

Heavy metals content |

mineralisation/spectro AA |

<1 |

ppm |

|

Refractometer correction factor |

- |

x1.5 |

|

|

Copper blade corrosion |

NF EN ISO 2160 |

1a |

|

|

Copper blade corrosion |

NF EN ISO 2160 |

1a |

|

PRESENTATIONS

|

Drum 200 kg

|

Can 20 kg

|

cardboard of 4x 5kg

|

Looking for another product?

|

Discover our entire range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.